Barney the Beaver Returns

This time, he brought a friend.

Lawn vs Machine

Battery break. Forgot to charge it the last time.

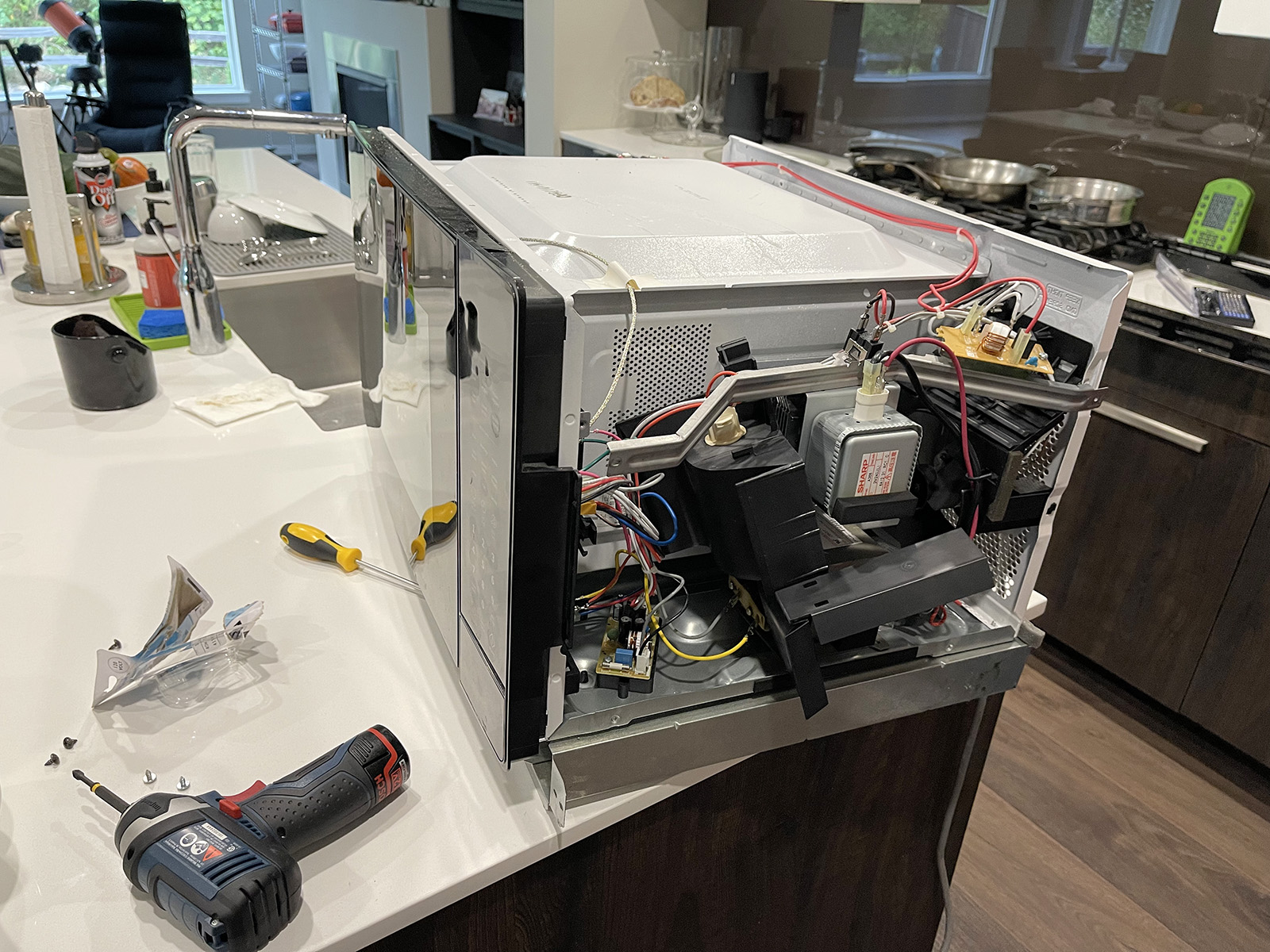

So you want to replace a light bulb?

You’re going to need power equipment and ladders to change the bulb in this Electrolux microwave. First, use a Phillips head screwdriver to remove four screws that hold the trim plate in place. Set it aside and slide the unit halfway out of the cabinet while someone else disconnects the power cord. Except you can’t […]

Rainy Sunday

Spring was unusually warm and dry in the Seattle area but the weekend brought cool temps and plenty of rain.

FedEx 397

MD11F on approach to SEA on Sunday, 30 May 2021

Mama Duck and the Ducklings

Mama Duck and her ducklings make their way to the nearby pond.

Saturday Piano Practice

New piano. Rusty fingers.